BSC’s Custom Cable Department

As an accredited custom cable manufacturer, BSC can meet any job’s distinct needs, specifications, or other requirements. Our product lines aren’t limited to the standard assemblies that most manufacturers build and adhere to. Instead, we rely on the talent, ability, and proficiency of our experienced team of product engineers to create customized cabling and assembly solutions for our customers.

We can translate your ideas into project-specific assemblies, produce a sample for your approval, and build out the requested assemblies, all according to our high standards of quality control. We can provide specific lengths, breakouts, brand names, material types, and even custom labeling, bundling, and packaging.

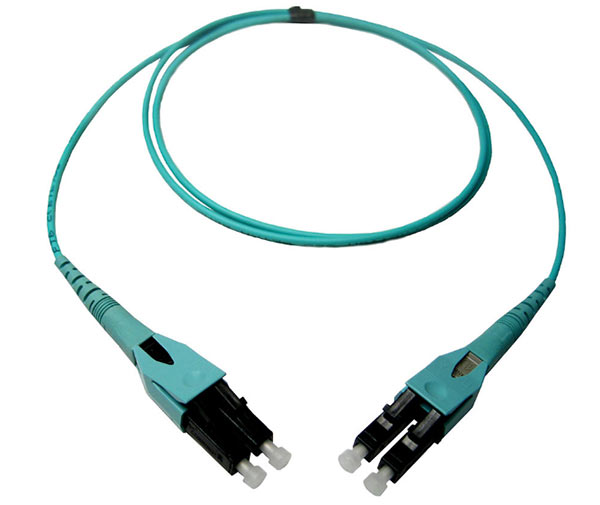

BSC’s Fiber Optic Cable Department

To get just about any cabling job done, we feature a variety of cords: C Series: Corning Gold; T Series: TAA Compliant; and E Series, Economy-Light Line. For each of our assemblies, all terminations are fully tested to industry standards and won’t be passed unless they meet all manufacturer specifications.

BSC continually invests in fiber testing equipment to ensure we are keeping pace with industry practice. Our fiber room features three testing stations, capable of IL/RL testing, Fiber check Pro software and a separate station for our new Norland GL16-Aio Interferometer.

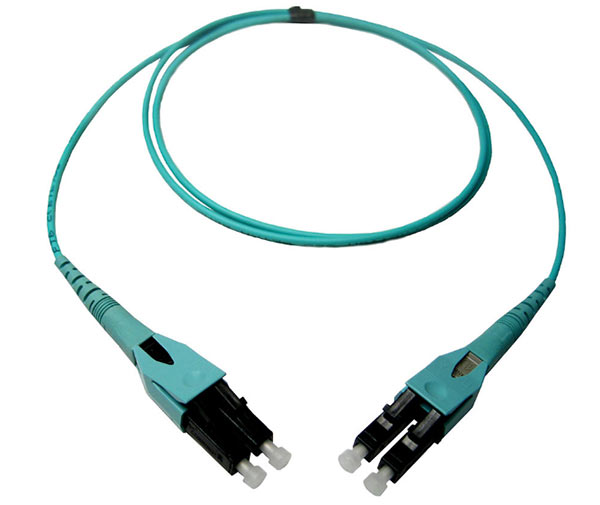

BSC’s Fiber Optic Cable Department

To get just about any cabling job done, we feature a variety of cords: C Series: Corning Gold; T Series: TAA Compliant; and E Series, Economy-Light Line. For each of our assemblies, all terminations are fully tested to industry standards and won’t be passed unless they meet all manufacturer specifications.

BSC continually invests in fiber testing equipment to ensure we are keeping pace with industry practice. Our fiber room features three testing stations, capable of IL/RL testing, Fiber check Pro software and a separate station for our new Norland GL16-Aio Interferometer.

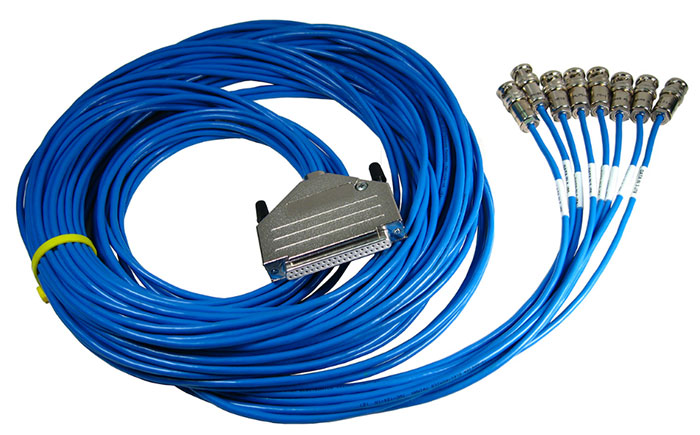

BSC’s Copper and Telco Cable Department

We feature a wide range of all types of copper cabling, from patch cords, to custom cable harnesses, and everything in between. Vendors in the industry have been cutting corners to make copper assemblies more cost effective by using non-UL approved cable or by using Copper Clad Aluminum conductors (CCAs).

Quality That’s Second to None

At B.S. Cable Company, Inc., we provide durable and high-quality products to help our customers get the job done, no matter what. In fact, it’s why we like to say that we’re “Relentless Until a Solution Is Found.” Our cabling assembly house (CAH), located in the heart of Harleysville, PA, is known throughout the industry for our expertise and experience in providing dependable custom cable assemblies.

Not only is our fiber manufacturing process audited by Corning each year as part of their Gold House Certification Program, but we have also been ISO certified since 2001, meaning that we have been recognized as implementing a quality standards management system. In short, we provide our customers with products they can count on.

A focus on quality control isn’t just what drives us at BSC. We’re also dedicated to offering affordable and cost-effective cabling and assembly solutions, all to help your customers get the job done.